You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

What are the core advantages of odorless E0 grade environmentally friendly particleboard

source:m.33w4.com Time:2025-08-11

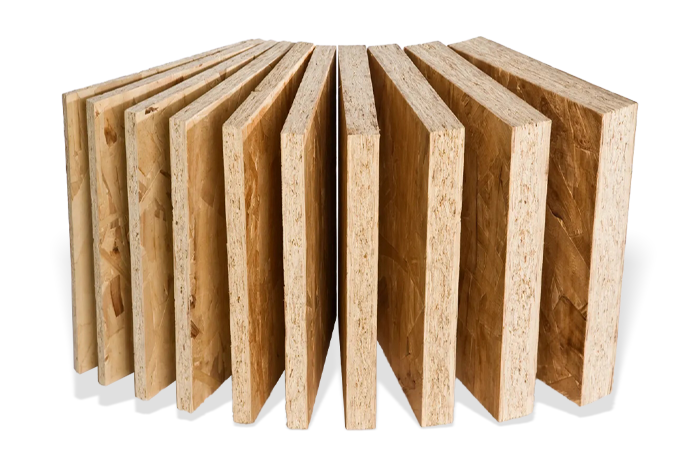

Odorless E0 grade environmentally friendly particleboard is a category of particleboard, with core advantages focused on environmental friendliness, health, user experience, and applicability. Specifically, it can be broken down into the following points:

1、 Low formaldehyde emission

The core manifestation of E0 level standard:

According to China's Limited Amount of Formaldehyde Emission from Wood based Panels (GB 18580-2017), the formaldehyde emission of Grade E0 particleboard is ≤ 0.124mg/m 3 (climate box method), which is only Grade E1 (≤ 0.124mg/m 3 is the same as the standard value of Grade E1, but in actual production, Grade E0 is mostly a stricter standard for enterprise internal control, and some companies can achieve the lower limit level of ≤ 0.05mg/m 3), even lower than the formaldehyde emission of wood itself in the natural environment (about 0.1mg/m 3).

This indicator means that very little urea formaldehyde resin adhesive is used in the production process of the board, or formaldehyde free adhesive (such as MDI adhesive) is used to reduce formaldehyde volatilization from the source, which meets the environmental requirements of "almost formaldehyde free".

2. Complies with strict international standards:

Some odorless E0 grade particleboard has also passed certifications such as CARB P2 in the United States and CE in the European Union, with stricter requirements for formaldehyde emissions (such as CARB P2 requiring ≤ 0.09mg/m 3), which can meet the environmental protection needs of exports or indoor environments.

2、 Odorless feature enhances health and user experience

1. No unpleasant odor:

Traditional particleboard may have residual unpleasant odors such as formaldehyde and phenol due to improper adhesive or wood treatment. Long term inhalation can cause dizziness and respiratory discomfort. Odorless E0 grade particleboard, by optimizing adhesives (such as using plant-based adhesives and formaldehyde free adhesives) and processes (such as high-temperature hot pressing deodorization), removes odor sources from the production process. After opening or installation, there is basically no pungent odor, and it can be quickly put into use without the need for long-term ventilation and odor dissipation.

2. More friendly to sensitive populations:

Especially suitable for enclosed spaces such as children's rooms, bedrooms, and elderly rooms, or for people who are sensitive to odors (such as pregnant women and asthma patients), reducing health hazards caused by odors and improving living comfort.

3、 Balanced physical performance to meet diverse usage needs

1. Stable structure and not easily deformed:

Particle board is made by pressing wood chips under high temperature and high pressure, with a uniform internal structure, better lateral load-bearing capacity than plywood, and lower water absorption and expansion rate. After being combined with edge sealing technology, it can effectively resist the influence of humid environments (such as dry areas in kitchens and bathrooms), reducing warping and cracking problems.

2. Excellent processing performance:

The surface can be directly treated with veneer (melamine impregnated paper, wood veneer), spray painting, film coating, etc., suitable for various decorative styles; And it is easy to cut, drill, and slot, suitable for the complex styling needs of customized furniture such as wardrobes, cabinets, and TV cabinets, with high production efficiency.

4、 Outstanding cost-effectiveness, balancing environmental protection and cost

Compared to pure solid wood panels, odorless E0 grade particleboard has a lower price (about 1/3-1/2 of solid wood of the same specification), and fully utilizes wood chips, which conforms to the concept of resource recycling, reduces the consumption of logs, and combines environmental protection and economy.

Compared with other environmentally friendly boards such as formaldehyde free particle board and multi-layer solid wood board, its production process is mature, the supply chain is stable, and it can control the terminal price while ensuring E0 level environmental protection, which is suitable for the needs of the mass market.

5、 Widely applicable scenarios, suitable for multi domain needs

Indoor furniture: wardrobes, shoe cabinets, bookcases, bedside tables, etc., which come into direct contact with the human body, are particularly important for environmental friendliness and odorlessness;

Office space: desks, filing cabinets, etc., to reduce formaldehyde pollution in the office environment and improve work comfort;

Commercial venues: shopping mall display cabinets, hotel furniture, etc., need to be quickly put into use and meet environmental acceptance standards.

1、 Low formaldehyde emission

The core manifestation of E0 level standard:

According to China's Limited Amount of Formaldehyde Emission from Wood based Panels (GB 18580-2017), the formaldehyde emission of Grade E0 particleboard is ≤ 0.124mg/m 3 (climate box method), which is only Grade E1 (≤ 0.124mg/m 3 is the same as the standard value of Grade E1, but in actual production, Grade E0 is mostly a stricter standard for enterprise internal control, and some companies can achieve the lower limit level of ≤ 0.05mg/m 3), even lower than the formaldehyde emission of wood itself in the natural environment (about 0.1mg/m 3).

This indicator means that very little urea formaldehyde resin adhesive is used in the production process of the board, or formaldehyde free adhesive (such as MDI adhesive) is used to reduce formaldehyde volatilization from the source, which meets the environmental requirements of "almost formaldehyde free".

2. Complies with strict international standards:

Some odorless E0 grade particleboard has also passed certifications such as CARB P2 in the United States and CE in the European Union, with stricter requirements for formaldehyde emissions (such as CARB P2 requiring ≤ 0.09mg/m 3), which can meet the environmental protection needs of exports or indoor environments.

2、 Odorless feature enhances health and user experience

1. No unpleasant odor:

Traditional particleboard may have residual unpleasant odors such as formaldehyde and phenol due to improper adhesive or wood treatment. Long term inhalation can cause dizziness and respiratory discomfort. Odorless E0 grade particleboard, by optimizing adhesives (such as using plant-based adhesives and formaldehyde free adhesives) and processes (such as high-temperature hot pressing deodorization), removes odor sources from the production process. After opening or installation, there is basically no pungent odor, and it can be quickly put into use without the need for long-term ventilation and odor dissipation.

2. More friendly to sensitive populations:

Especially suitable for enclosed spaces such as children's rooms, bedrooms, and elderly rooms, or for people who are sensitive to odors (such as pregnant women and asthma patients), reducing health hazards caused by odors and improving living comfort.

3、 Balanced physical performance to meet diverse usage needs

1. Stable structure and not easily deformed:

Particle board is made by pressing wood chips under high temperature and high pressure, with a uniform internal structure, better lateral load-bearing capacity than plywood, and lower water absorption and expansion rate. After being combined with edge sealing technology, it can effectively resist the influence of humid environments (such as dry areas in kitchens and bathrooms), reducing warping and cracking problems.

2. Excellent processing performance:

The surface can be directly treated with veneer (melamine impregnated paper, wood veneer), spray painting, film coating, etc., suitable for various decorative styles; And it is easy to cut, drill, and slot, suitable for the complex styling needs of customized furniture such as wardrobes, cabinets, and TV cabinets, with high production efficiency.

4、 Outstanding cost-effectiveness, balancing environmental protection and cost

Compared to pure solid wood panels, odorless E0 grade particleboard has a lower price (about 1/3-1/2 of solid wood of the same specification), and fully utilizes wood chips, which conforms to the concept of resource recycling, reduces the consumption of logs, and combines environmental protection and economy.

Compared with other environmentally friendly boards such as formaldehyde free particle board and multi-layer solid wood board, its production process is mature, the supply chain is stable, and it can control the terminal price while ensuring E0 level environmental protection, which is suitable for the needs of the mass market.

5、 Widely applicable scenarios, suitable for multi domain needs

Indoor furniture: wardrobes, shoe cabinets, bookcases, bedside tables, etc., which come into direct contact with the human body, are particularly important for environmental friendliness and odorlessness;

Office space: desks, filing cabinets, etc., to reduce formaldehyde pollution in the office environment and improve work comfort;

Commercial venues: shopping mall display cabinets, hotel furniture, etc., need to be quickly put into use and meet environmental acceptance standards.

Previous:

What is the moisture-proof and waterproof perform…

Next:

Why is it said that formaldehyde free ENF grade e…

Related articles

Related products

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell