You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

What are the physical properties of odorless E0 grade environmentally friendly particleboard

source:m.33w4.com Time:2025-07-28

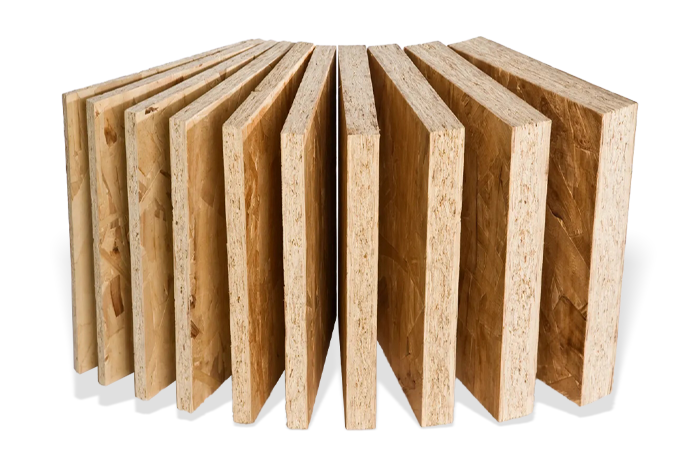

Odorless E0 grade environmentally friendly particleboard is a category of particleboard with a higher environmental protection level (formaldehyde emission ≤ 0.5mg/m 3) and has undergone deodorization treatment. Its physical properties balance structural stability and adaptability to use, as shown below:

1、 Basic mechanical properties: meet the requirements of basic load-bearing and deformation resistance

1. Static bending strength

Numerical range: usually between 12-25MPa (with significant differences in thickness and density), medium to high-density products (density ≥ 0.7g/cm 3) can reach over 20MPa.

Performance significance: It reflects the ability of the board to withstand bending loads. The higher the value, the less likely it is to bend or break in scenarios such as furniture countertops and cabinet partitions. For example, when used for bookshelf shelves, it can stably carry the weight of books without significant sagging.

2. Elastic modulus

Numerical range: approximately 2500-4500MPa, positively correlated with density.

Performance significance: It represents the stiffness of the material during the elastic deformation stage. The higher the value, the smaller the elastic deformation of the board under stress (such as a slight impact when the cabinet door is closed, which is less likely to cause the board surface to sink).

3. Internal bonding strength

Numerical range: generally ≥ 0.7MPa (qualified product standard), excellent products can reach 1.0MPa or above.

Performance significance: Measuring the bonding strength between shavings directly affects the board's ability to resist delamination and peeling. Plates with high internal bonding strength are less prone to local cracking or loose screws when drilling holes or installing hardware components such as hinges and screws.

2、 Moisture and Water Resistance: Different Performance Due to Process Differences

1. Water absorption thickness expansion rate

Ordinary E0 grade particleboard: After soaking in water at (20 ± 1) ℃ for 2 hours, the thickness expansion rate is usually ≤ 12% (qualified product), and excellent products can be controlled within 8%.

Moisture resistant E0 grade particleboard (with added moisture-proof agent or melamine adhesive): After soaking for 24 hours, the expansion rate is ≤ 10%, suitable for environments with high humidity (such as dry areas in kitchens and bathrooms).

Limitations: The overall water resistance is weaker than solid wood particle board or multi-layer board, and long-term immersion can cause structural collapse. Therefore, it is not recommended for use in scenarios where it comes into direct contact with water.

2. Moisture content

Standard range: 6% -14% (national standard requirement), but in actual production, it is mostly controlled at 8% -12%, matching the humidity of the usage environment (such as slightly lower in dry areas in the north and slightly higher in humid areas in the south).

Impact: Plates with stable moisture content are less likely to warp or crack due to changes in environmental humidity, ensuring dimensional stability.

3、 Dimensional stability: reduce the risk of deformation

Thickness deviation: Superior products allow a deviation of ± 0.3mm to ensure flatness during splicing or veneering (such as the flat seam between the side panel and top panel of a customized wardrobe).

Static bending deformation: Under rated load, the bending deflection is small (such as a 2440mm × 1220mm plate, with a middle deflection of ≤ L/250 when supported at both ends, where L is the span), and long-term use is not prone to deformation.

Anti warping: Through symmetrical paving technology (with symmetrical particle size and direction between the surface and bottom layers), the warping caused by uneven internal stress is reduced, making it suitable for large-scale use (such as background walls and cabinet side panels).

4、 Surface performance: Suitable for various finishing techniques

1. Surface smoothness

The surface layer is made of fine shavings or fiber layers, and after hot pressing, the surface flatness is high (Ra value ≤ 10 μ m). It can be directly veneered (melamine impregnated paper, PVC film, wood veneer, etc.), and is not prone to bubbling or wrinkling.

2. Wear resistance and stain resistance

The surface wear resistance of untreated particleboard is generally average (easily scratched by sharp objects), but the wear resistance of E0 grade particleboard after finishing (such as melamine veneer) can reach over 400 revolutions per minute (in accordance with GB/T 4897 standard), and the surface is smooth and easy to clean. Stains such as soy sauce and oil stains can be quickly wiped off.

5、 The correlation between environmental performance and "odorless" characteristics

Formaldehyde emission: The core indicator for E0 level is ≤ 0.5mg/m 3 (climate chamber method), which is much lower than E1 level (≤ 1.5mg/m 3), reducing unpleasant odors from the source.

Odorless treatment: By optimizing the adhesive (such as using MDI ecological adhesive, which does not contain formaldehyde), adding deodorizers, or extending the aging time, the release of volatile organic compounds (VOCs) can be further reduced to achieve a "tasteless" experience, suitable for odor sensitive spaces such as children's rooms and bedrooms.

1、 Basic mechanical properties: meet the requirements of basic load-bearing and deformation resistance

1. Static bending strength

Numerical range: usually between 12-25MPa (with significant differences in thickness and density), medium to high-density products (density ≥ 0.7g/cm 3) can reach over 20MPa.

Performance significance: It reflects the ability of the board to withstand bending loads. The higher the value, the less likely it is to bend or break in scenarios such as furniture countertops and cabinet partitions. For example, when used for bookshelf shelves, it can stably carry the weight of books without significant sagging.

2. Elastic modulus

Numerical range: approximately 2500-4500MPa, positively correlated with density.

Performance significance: It represents the stiffness of the material during the elastic deformation stage. The higher the value, the smaller the elastic deformation of the board under stress (such as a slight impact when the cabinet door is closed, which is less likely to cause the board surface to sink).

3. Internal bonding strength

Numerical range: generally ≥ 0.7MPa (qualified product standard), excellent products can reach 1.0MPa or above.

Performance significance: Measuring the bonding strength between shavings directly affects the board's ability to resist delamination and peeling. Plates with high internal bonding strength are less prone to local cracking or loose screws when drilling holes or installing hardware components such as hinges and screws.

2、 Moisture and Water Resistance: Different Performance Due to Process Differences

1. Water absorption thickness expansion rate

Ordinary E0 grade particleboard: After soaking in water at (20 ± 1) ℃ for 2 hours, the thickness expansion rate is usually ≤ 12% (qualified product), and excellent products can be controlled within 8%.

Moisture resistant E0 grade particleboard (with added moisture-proof agent or melamine adhesive): After soaking for 24 hours, the expansion rate is ≤ 10%, suitable for environments with high humidity (such as dry areas in kitchens and bathrooms).

Limitations: The overall water resistance is weaker than solid wood particle board or multi-layer board, and long-term immersion can cause structural collapse. Therefore, it is not recommended for use in scenarios where it comes into direct contact with water.

2. Moisture content

Standard range: 6% -14% (national standard requirement), but in actual production, it is mostly controlled at 8% -12%, matching the humidity of the usage environment (such as slightly lower in dry areas in the north and slightly higher in humid areas in the south).

Impact: Plates with stable moisture content are less likely to warp or crack due to changes in environmental humidity, ensuring dimensional stability.

3、 Dimensional stability: reduce the risk of deformation

Thickness deviation: Superior products allow a deviation of ± 0.3mm to ensure flatness during splicing or veneering (such as the flat seam between the side panel and top panel of a customized wardrobe).

Static bending deformation: Under rated load, the bending deflection is small (such as a 2440mm × 1220mm plate, with a middle deflection of ≤ L/250 when supported at both ends, where L is the span), and long-term use is not prone to deformation.

Anti warping: Through symmetrical paving technology (with symmetrical particle size and direction between the surface and bottom layers), the warping caused by uneven internal stress is reduced, making it suitable for large-scale use (such as background walls and cabinet side panels).

4、 Surface performance: Suitable for various finishing techniques

1. Surface smoothness

The surface layer is made of fine shavings or fiber layers, and after hot pressing, the surface flatness is high (Ra value ≤ 10 μ m). It can be directly veneered (melamine impregnated paper, PVC film, wood veneer, etc.), and is not prone to bubbling or wrinkling.

2. Wear resistance and stain resistance

The surface wear resistance of untreated particleboard is generally average (easily scratched by sharp objects), but the wear resistance of E0 grade particleboard after finishing (such as melamine veneer) can reach over 400 revolutions per minute (in accordance with GB/T 4897 standard), and the surface is smooth and easy to clean. Stains such as soy sauce and oil stains can be quickly wiped off.

5、 The correlation between environmental performance and "odorless" characteristics

Formaldehyde emission: The core indicator for E0 level is ≤ 0.5mg/m 3 (climate chamber method), which is much lower than E1 level (≤ 1.5mg/m 3), reducing unpleasant odors from the source.

Odorless treatment: By optimizing the adhesive (such as using MDI ecological adhesive, which does not contain formaldehyde), adding deodorizers, or extending the aging time, the release of volatile organic compounds (VOCs) can be further reduced to achieve a "tasteless" experience, suitable for odor sensitive spaces such as children's rooms and bedrooms.

Previous:

Why is it said that formaldehyde free ENF grade e…

Next:

Which groups of people prefer formaldehyde free E…

Related articles

Related products

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell