You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

Why is it said that formaldehyde free ENF grade environmentally friendly particleboard is more conve

source:m.33w4.com Time:2025-08-04

Formaldehyde free ENF grade environmentally friendly particle board (hereinafter referred to as "formaldehyde free ENF particle board") is considered to be easy to process and closely related to its material characteristics, production process, and performance advantages. ENF level is the higher environmental protection level (≤ 0.025mg/m 3) of formaldehyde emission from wood-based panels in China, and "formaldehyde free" means that formaldehyde containing adhesives are not used in the production process (such as MDI adhesive and other formaldehyde free adhesives). The processing convenience of this type of board is mainly reflected in the following aspects:

1、 Uniform material, high stability, and not easily deformed during processing

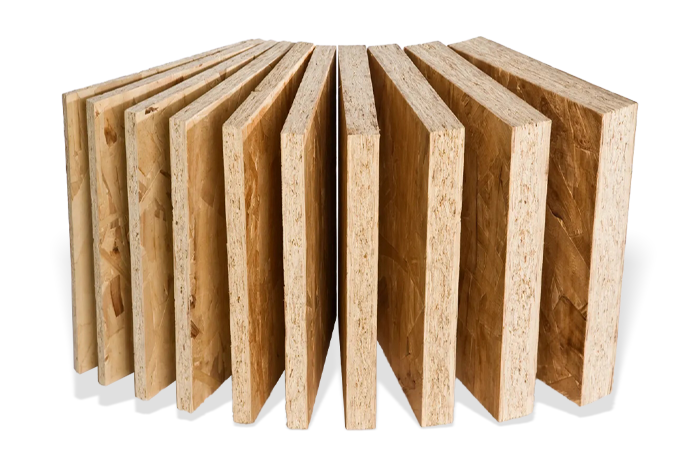

Structural characteristics: Particle board is made by pressing wood shavings (shavings) under high temperature and high pressure. Non aldehyde ENF grade products have stable adhesive properties (such as strong bonding strength of MDI) in production, and the internal density distribution of the board is more uniform, avoiding the texture differences, knots, and uneven stress of natural wood.

Processing advantages:

It is not easy to experience "edge breakage" or "cracking" during cutting, especially when performing straight or irregular cutting. The high flatness of the edges reduces the workload of subsequent trimming;

When drilling and slotting, the internal structure of the board is stable and not easily deformed or broken due to local stress, making it suitable for precision machining (such as drilling and positioning furniture connectors).

2、 Strong adaptability of surface treatment, easy to achieve diversified processing

Veneering and coating friendly: The formaldehyde free ENF particle board has a smooth surface without obvious defects (such as bubbles and delamination), and can be directly veneered (such as using melamine impregnated paper, PVC film, wood veneer, etc.). The adhesive has strong adhesion and is not easy to peel or peel off;

If direct painting is required (such as spray painting or brushing), the surface pores are evenly distributed, the primer has good adsorption, can reduce the amount of paint used, and the paint surface has high flatness.

Convenient secondary processing: Complex shapes can be achieved through processes such as edge sealing, milling, and carving, such as curved edges and groove designs for furniture. During the processing, the board is not easily cracked and the integrity of the shape can be maintained.

3、 Moderate density and hardness, minimal tool wear during processing

Hardness balance: The density of formaldehyde free ENF particleboard is usually between 0.6-0.8g/cm 3, with moderate hardness (lower than high-density fiberboard and higher than soft wood). During processing, it has less wear on cutting tools (such as saw blades and milling cutters), extending tool life and reducing processing costs.

Easy machinability: Compared to natural hardwood or high-density boards, it has lower cutting resistance and can be processed using ordinary woodworking machinery (such as panel saws, edge banding machines, drilling machines) without the need for special equipment. It is suitable for small and medium-sized processing plants or family workshops to operate.

4、 Unified size specifications to reduce processing errors

Industrialized production of formaldehyde free ENF particleboard typically has strict dimensional tolerances (such as thickness deviation ≤ 0.3mm, length/width deviation ≤ 1mm), high board flatness (low warpage), and high fitting accuracy between boards during batch processing (such as furniture component assembly), reducing assembly problems caused by dimensional errors and improving processing efficiency.

5、 Environmental characteristics do not affect processing compatibility

The formaldehyde free adhesive used in ENF particleboard (such as MDI adhesive) has good chemical stability. During the processing (such as cutting, heating and edge sealing), it will not release harmful substances, nor will it react chemically with processing tools and auxiliary materials (such as edge sealing tape adhesive, paint). Therefore, no special protective measures are required, and it can share the processing flow and equipment with traditional particleboard, with strong compatibility.

1、 Uniform material, high stability, and not easily deformed during processing

Structural characteristics: Particle board is made by pressing wood shavings (shavings) under high temperature and high pressure. Non aldehyde ENF grade products have stable adhesive properties (such as strong bonding strength of MDI) in production, and the internal density distribution of the board is more uniform, avoiding the texture differences, knots, and uneven stress of natural wood.

Processing advantages:

It is not easy to experience "edge breakage" or "cracking" during cutting, especially when performing straight or irregular cutting. The high flatness of the edges reduces the workload of subsequent trimming;

When drilling and slotting, the internal structure of the board is stable and not easily deformed or broken due to local stress, making it suitable for precision machining (such as drilling and positioning furniture connectors).

2、 Strong adaptability of surface treatment, easy to achieve diversified processing

Veneering and coating friendly: The formaldehyde free ENF particle board has a smooth surface without obvious defects (such as bubbles and delamination), and can be directly veneered (such as using melamine impregnated paper, PVC film, wood veneer, etc.). The adhesive has strong adhesion and is not easy to peel or peel off;

If direct painting is required (such as spray painting or brushing), the surface pores are evenly distributed, the primer has good adsorption, can reduce the amount of paint used, and the paint surface has high flatness.

Convenient secondary processing: Complex shapes can be achieved through processes such as edge sealing, milling, and carving, such as curved edges and groove designs for furniture. During the processing, the board is not easily cracked and the integrity of the shape can be maintained.

3、 Moderate density and hardness, minimal tool wear during processing

Hardness balance: The density of formaldehyde free ENF particleboard is usually between 0.6-0.8g/cm 3, with moderate hardness (lower than high-density fiberboard and higher than soft wood). During processing, it has less wear on cutting tools (such as saw blades and milling cutters), extending tool life and reducing processing costs.

Easy machinability: Compared to natural hardwood or high-density boards, it has lower cutting resistance and can be processed using ordinary woodworking machinery (such as panel saws, edge banding machines, drilling machines) without the need for special equipment. It is suitable for small and medium-sized processing plants or family workshops to operate.

4、 Unified size specifications to reduce processing errors

Industrialized production of formaldehyde free ENF particleboard typically has strict dimensional tolerances (such as thickness deviation ≤ 0.3mm, length/width deviation ≤ 1mm), high board flatness (low warpage), and high fitting accuracy between boards during batch processing (such as furniture component assembly), reducing assembly problems caused by dimensional errors and improving processing efficiency.

5、 Environmental characteristics do not affect processing compatibility

The formaldehyde free adhesive used in ENF particleboard (such as MDI adhesive) has good chemical stability. During the processing (such as cutting, heating and edge sealing), it will not release harmful substances, nor will it react chemically with processing tools and auxiliary materials (such as edge sealing tape adhesive, paint). Therefore, no special protective measures are required, and it can share the processing flow and equipment with traditional particleboard, with strong compatibility.

Previous:

What are the core advantages of odorless E0 grade…

Next:

What are the physical properties of odorless E0 g…

Related articles

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell